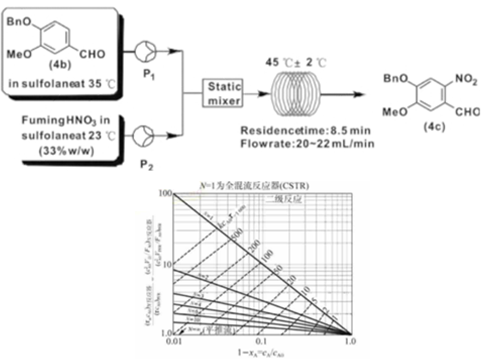

Nitration Reaction

-

Process:

HNO3-H2SO4 nitrification(Homogeneous);

HNO3-H2SO4 nitrification(Heterogeneous);

Thin nitric acid nitration;HNO3-HAc nitration;

-

Equipments:

Microchannel Reactor;Tubular Reactor;

Microchannel+Tubular;CSTRsCSTRs + PFR

-

Advantage:

Process safety of nitrification reaction;

Post-treatment;Waste acid recovery prcess package

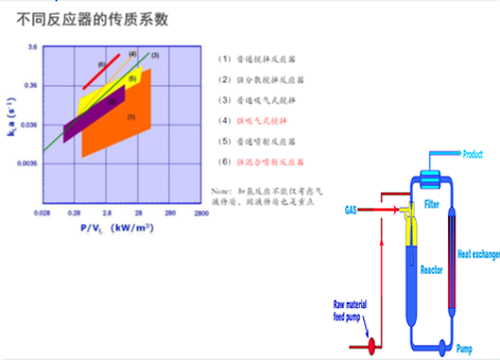

Oxidation Reaction

-

Process:

Air/O2 oxidation;H2O2 oxidation ;O3 oxidation;

HNO3 oxidation;Tempo oxidation;Swan oxidation;

Column Reactor;Tubular reactor;Trickle bed;

-

Advantages:

Heat and mass transfer enhancement of heterogeneous system in tubular reactor;

Countermeasures for product precipitation after oxidation;

Research and development of supported oxidation catalysts;

Safety control strategy of air oxidation Column;

Continuous air oxidation & overall design of continuous distillation;

PhotoChemical Reaction

-

Process/Equipments:

Reactor/Column Reactor- internal light(CSTRs);

Tubular Reactor- External light(PFR);

LOOP Reactor- External light;Microchannel- Laternal light;

-

Advantages:

Mechanism of various photo reactions;

Selection and design of various photoreactors Design and manufacture of various mercury lamps, LED lamps and cooling systems;

Spectrum test, transmittance test;Configuration of various filter fluids; Scale-up from lab-size to industrial-size;

Diazotization Reaction

-

Prcoess/Equipment:

Microchannel;

Tubular Reactor;

-

Advantage:

After the diazonium salt is prepared, it is continuously hydrolyzed to phenol hydroxyl;

Two steps in a row;The hydrolysis yield increased;

Hydrogenation Reaction

-

Equipments:

Gas-Liquild Ejector;Reactor;

Trickle Bed(Gas liquid solid three phase);

Fixed Bed(Gas-Solid);

High pressure CSTRs;

-

Advantage:

Continuous filtration and discharge system of catalyst;

Online continuous filtration batch or continuous production;

Process suitable for H2 / NH3 / CO2;

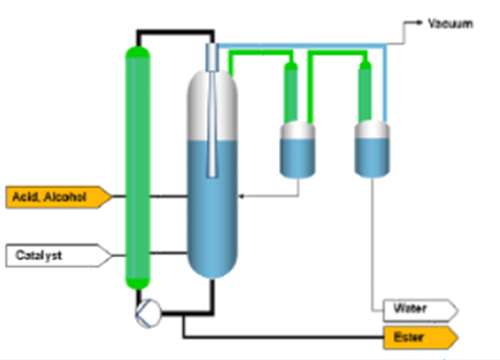

Esterification Reaction

-

Disadvantages of traditional esterification process:

Endothermic reaction;Equilibrium reaction;Long time;

Alcohol needs to be excessive;Continuous dehydration is required;

Sulfuric acid catalyst requires alkaline washing of the organic phase;

-

Reactive Distillation Process:

Column type continuous dehydration;

The reaction heat is used as the heating of the distillation Column;

-

Fixed Bed Process:

Solid acid as fixed bed;

Alcohol (excess) gas enters from the bottom; Azeotropic with water from the top;

Acid enters from the top of the bed;Continuous ester discharge from Column kettle;

Friedel-Crafts Reaction

-

Advantage 1:

Using solid acid catalyst, designed as a fixed bed;

Does not use a large amount of AlCl3;

-

Advantage 2:

Using ionic liquid catalyst;

Does not use a large amount of AlCl3;

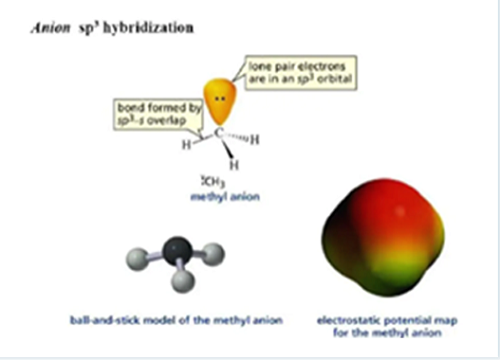

Grignard Reaction

-

Advantage:

Continuous synthesis of Grignard reagent;

Magnesium chips are added and reacted continuously;

Avoid causing problems;

Using Grignard reagent continuously;Grignard reagents without transfer and storage;

Bu-Li Reaction

-

Advantage:

Using microchannel reactor or tubular reactor;Continuous process;

"Butyl lithium hydrogen extraction" and "coupling" were carried out in two steps;

Increase the reaction temperature and avoid the use of liquid nitrogen;

Regular automatic cleaning;

Safe and reliable, with minimal liquid holdup;

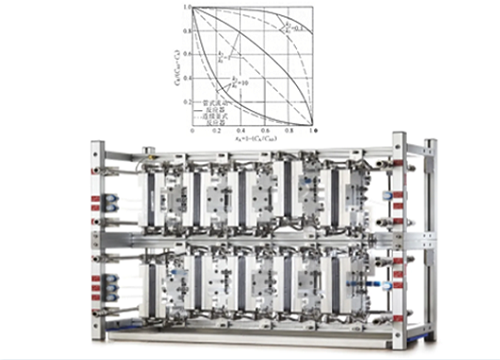

Reductive Amination Reaction

-

Advantage:

Using preferred catalyst;

Fixed bed process;

Reduction-amination completed at one time;

High efficiency;

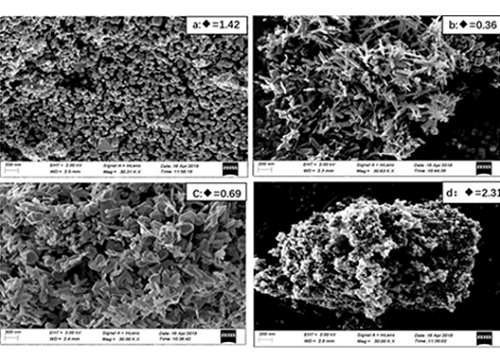

Solid Acid Catalyst

-

SO42- /MxOy solid Acid:

Non corrosive equipment;Stable to water;

The preparation is simple;Easy to separate from the product;

-

Application of solid acid:

Esterification reaction;Transesterification reaction;

Friedel-Crafts reaction;Catalytic nitrification;

Alkane isomerization;

Lonic Liquid Catalyst

-

Advantage:

Tasteless,nonflammable,extremely low steam pressure;

Can be used in high vacuum system;

Good solubility for both organic and inorganic substances, and can make the reaction proceed under homogeneous conditions;

Wide operating temperature range (- 40 ~ 300 );

Good thermal stability and chemical stability; Easy to separate from other substances;

-

Application:

Hydrogenation reaction;Friedel-Crafts reaction;

Diels alder reaction;Asymmetric catalysis;

Electrochemical research Acid gas capture and separation;

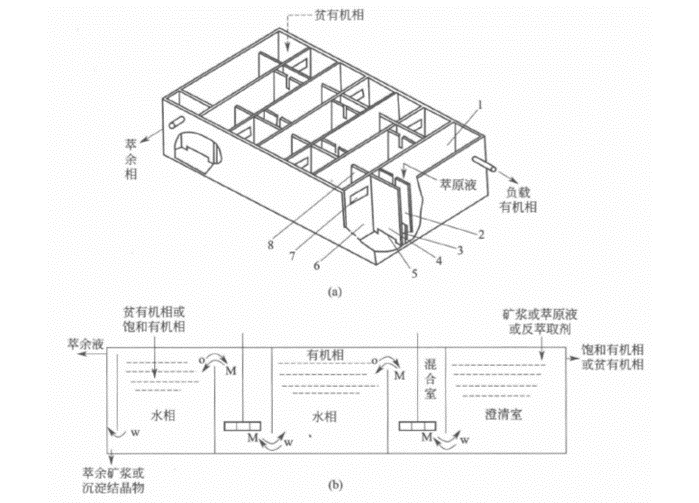

Continuous extraction

-

Two basic processes of extraction:

Extraction;(solubility,mass transfer coefficient)

Separation;(density difference,flow)

-

RDC Rotary extraction Column Design:

RDC Rotary extraction Column Design;

Centrifugal extractor Design;

Continuous Concentration

-

Continuous Concentration:

Continuous Concentration;

Continuous distillation

-

Advantages:

Stable product quality;

Low energy consumption;

Large production capacity;

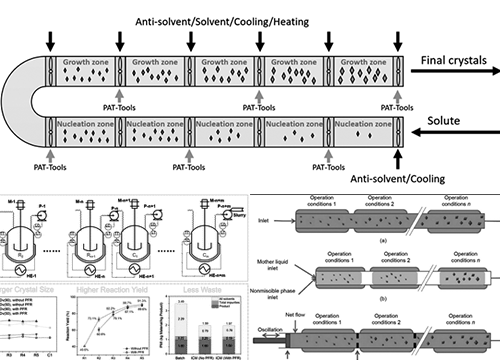

Continuous crystallization

-

Advantages:

The main crystal particle size stablable

Good particle size distribution;

Small amount of mother liquor;

High production capacity;

Low operation cost;

Process easy to control;