One of the development trends in the chemical industry is that the safe, clean, efficient, energy saving and sustainable, and continuous flow manufacturing is gaining rapid momentum as an innovative technology in the pharmaceutical and fine chemical industries. Key benefits of continuous flow include faster, safer reactions, which can result in a more environmentally friendly, smaller footprint, higher product quality and, crucially, the ability to perform chemical reactions that are difficult or impossible to perform in batch mode.

Flow Chemistry R&D Platform (Shanghai laboratory site, 16,000 square meters)

Flow chemistry mobile Equipments (25 sets)

Microchannel reactors

Tubular reactor

Continuous reactors (CSTRs)

Various types of photocatalytic reactors

Gas liquid injection reactor

Air oxidation column

Trickle bed/fixed bed

Rotary extraction column, centrifugal extractors

One of the development trends in the chemical industry is that the safe, clean, efficient, energy saving and sustainable, and continuous flow manufacturing is gaining rapid momentum as an innovative technology in the pharmaceutical and fine chemical industries. Key benefits of continuous flow include faster, safer reactions, which can result in a more environmentally friendly, smaller footprint, higher product quality and, crucially, the ability to perform chemical reactions that are difficult or impossible to perform in batch mode.

Flow Chemistry multi-purpose pilot plant (Jiangxi site pilot plant,2500 square meters)

Continuous CSTR reactors

Industrial microchannel reactor

Various tubular reactors

Multifunctional feed metering system

Various light reaction pilot devices

Continuous air oxidation column

Continuous Grignard reactors

Continuous extraction column

Multistage extraction centrifuge combination

Thin film evaporation

Molecular distillation

Continuous rectification

One of the development trends in the chemical industry is that the safe, clean, efficient, energy saving and sustainable, and continuous flow manufacturing is gaining rapid momentum as an innovative technology in the pharmaceutical and fine chemical industries. Key benefits of continuous flow include faster, safer reactions, which can result in a more environmentally friendly, smaller footprint, higher product quality and, crucially, the ability to perform chemical reactions that are difficult or impossible to perform in batch mode.

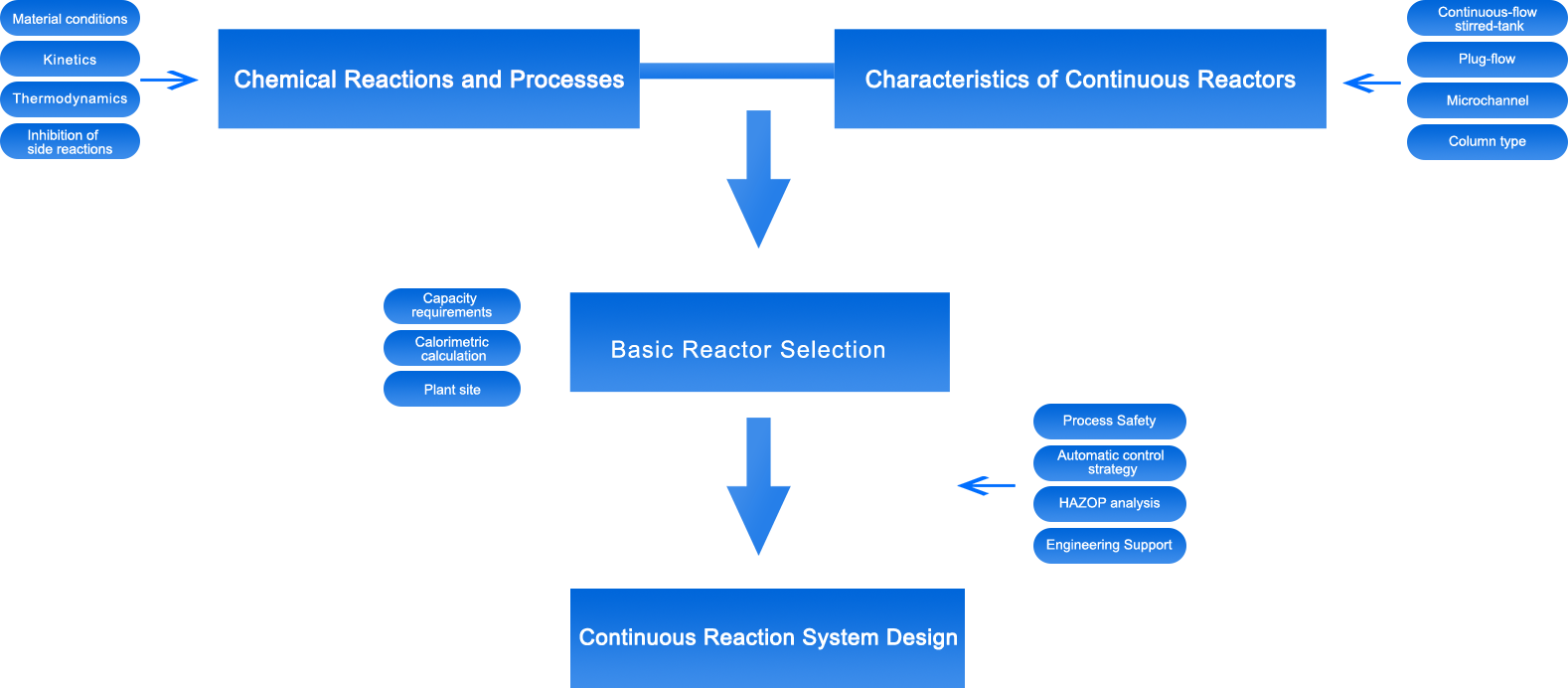

Process and equipment combinations

One of the development trends in the chemical industry is that the safe, clean, efficient, energy saving and sustainable, and continuous flow manufacturing is gaining rapid momentum as an innovative technology in the pharmaceutical and fine chemical industries. Key benefits of continuous flow include faster, safer reactions, which can result in a more environmentally friendly, smaller footprint, higher product quality and, crucially, the ability to perform chemical reactions that are difficult or impossible to perform in batch mode.

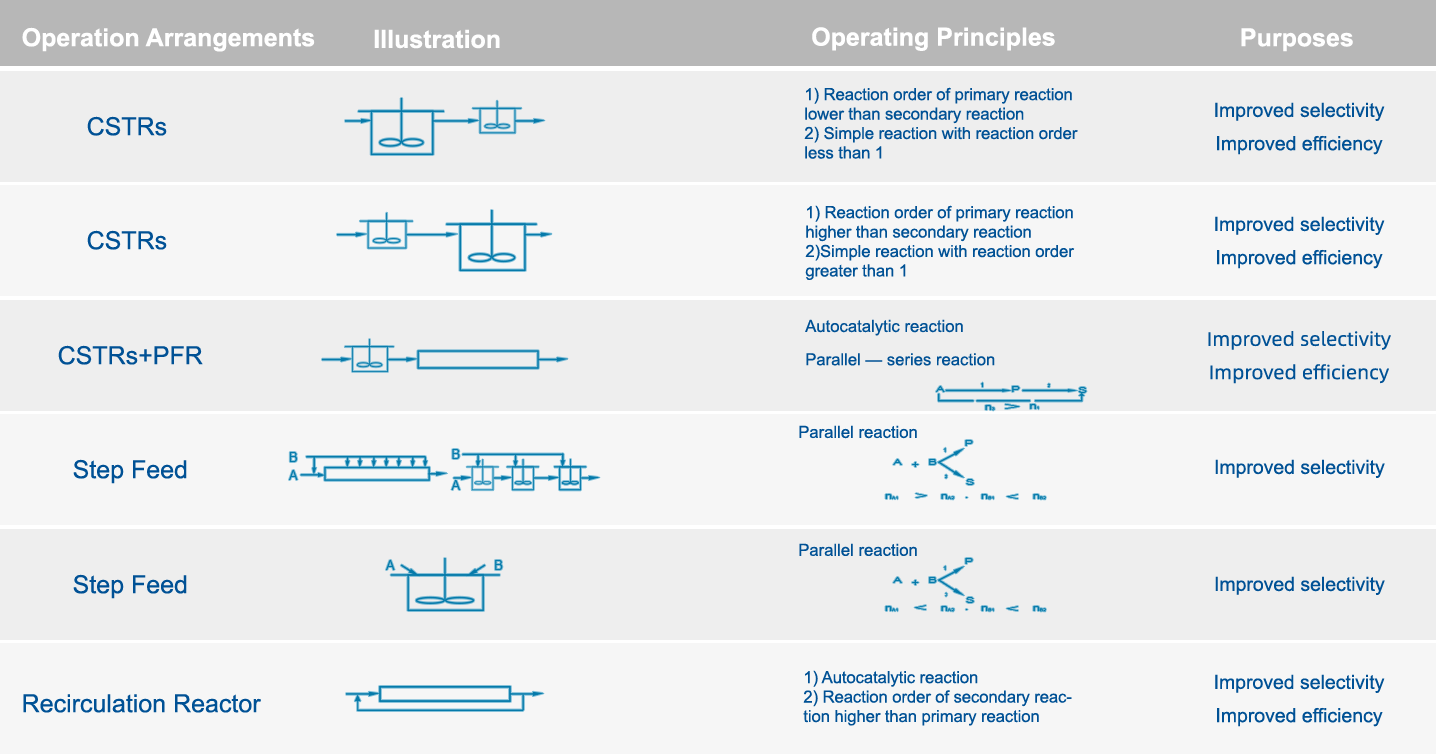

Combined application of continuous reactors

One of the development trends in the chemical industry is that the safe, clean, efficient, energy saving and sustainable, and continuous flow manufacturing is gaining rapid momentum as an innovative technology in the pharmaceutical and fine chemical industries. Key benefits of continuous flow include faster, safer reactions, which can result in a more environmentally friendly, smaller footprint, higher product quality and, crucially, the ability to perform chemical reactions that are difficult or impossible to perform in batch mode.

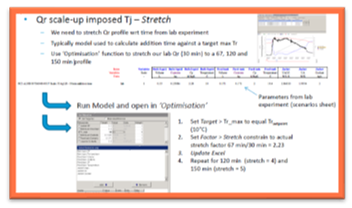

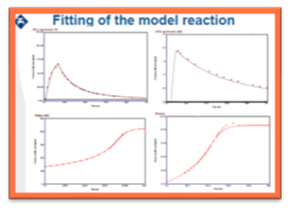

Using Dynochem software

Import RC-1 calorimetric data;

Import data of tubular reactor;

Establish reaction kinetics model;

Simulate the reaction under other continuous combination schemes;

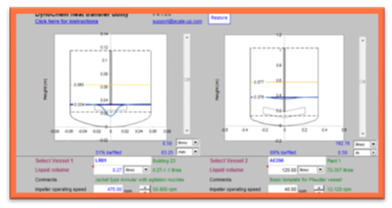

Measurement of mass and heat transfer;

Crystallographic simulation;

Gas liquid equilibrium calculation;

One of the development trends in the chemical industry is that the safe, clean, efficient, energy saving and sustainable, and continuous flow manufacturing is gaining rapid momentum as an innovative technology in the pharmaceutical and fine chemical industries. Key benefits of continuous flow include faster, safer reactions, which can result in a more environmentally friendly, smaller footprint, higher product quality and, crucially, the ability to perform chemical reactions that are difficult or impossible to perform in batch mode.

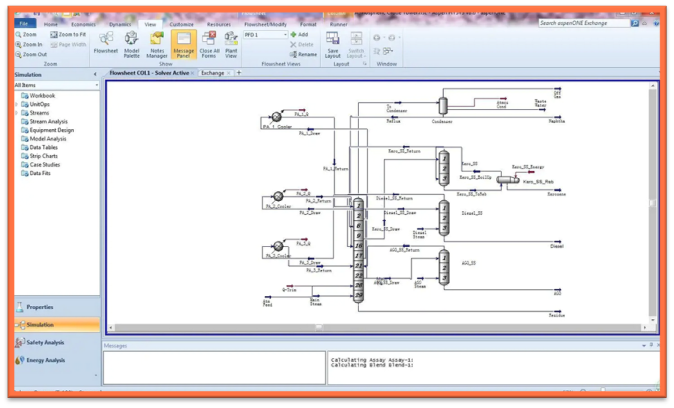

Using Aspen ChemCAD

A large number of physical property data;

Gas liquid / liquid liquid equilibrium data;

CSTR-PFR reactor calculation;

Heat exchanger calculation;

Calculation of continuous distillation column;

Heat balance accounting;

One of the development trends in the chemical industry is that the safe, clean, efficient, energy saving and sustainable, and continuous flow manufacturing is gaining rapid momentum as an innovative technology in the pharmaceutical and fine chemical industries. Key benefits of continuous flow include faster, safer reactions, which can result in a more environmentally friendly, smaller footprint, higher product quality and, crucially, the ability to perform chemical reactions that are difficult or impossible to perform in batch mode.

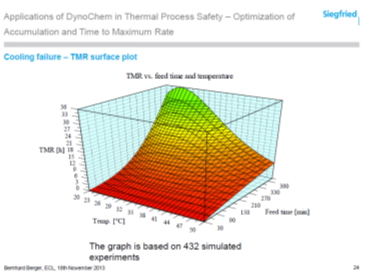

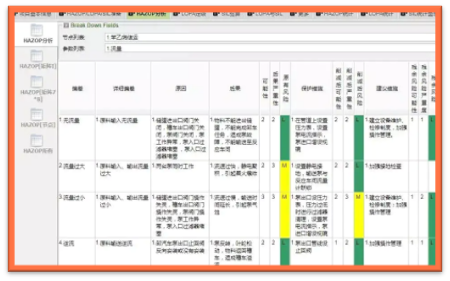

Safety risk

Calculation of various out of control models;

Disposal plan for damaged instruments and equipment;

Deviation disposal plan;

HAZOP analysis;

LOPA check calculation;

SIL grading;